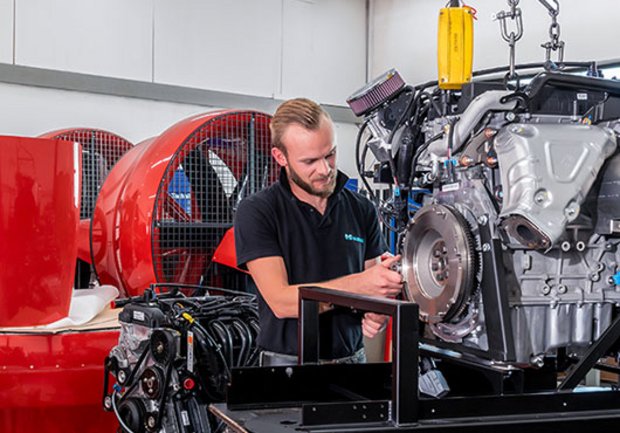

No off-the-shelf solutions

Our lighthouse project involves the production of large mobile fans, such as those used by fire brigades and rescue teams for positive pressure ventilation, smoke extraction, heat fighting or fresh air supply. We also use this production process successfully in the industrial sector. None of the resulting individual parts are standard products – every component is tailored to the customer’s requirements. We also manufacture systems for ultrasonic and hot plate welding of plastic parts, automation systems for filling, measuring and process monitoring, as well as control and adapters for robots.

Applications

Plastics technology

The constructive solutions developed by Huber Kunststoff & Technik can be found in almost every area of the plastics and automotive industry. Whenever standard approaches are not enough, we create and implement customised solutions – for example, we designed and manufactured a customised weighing conveyor cell complete with a marking and labelling device. This weighing conveyor cell was developed in accordance with the exact specifications of our customer and manufactured by us.

Fire extinguishing technology

A specialist solution developed by Huber Kunststoff & Technik involves the production of large mobile fans, which are primarily used for positive pressure ventilation and smoke control. In addition to the steel frame, electronics and cabling for these fans, we also produce the propellers and casings in-house, engineered precisely to our customers’ specifications and even including commissioning – on site if required.