Chlorine electrolysis plant

The OSEC plant for the production of sodium hypochlorite solutions produces the latter with a concentration below 1% via electrolysis of brine. The entire production process can also be automated. In accordance with the customer’s wishes, the cladding was designed and manufactured to be robust and simple, whereby the focus was on the essentials.

Control unit for sewer robot

When developing and producing thermoformed parts for a control unit for a sewer robot, our customer’s key requirement was to ensure the necessary stability by means of sufficiently thick materials. After finishing, the functional units were assembled at Huber Kunststoff & Technik.

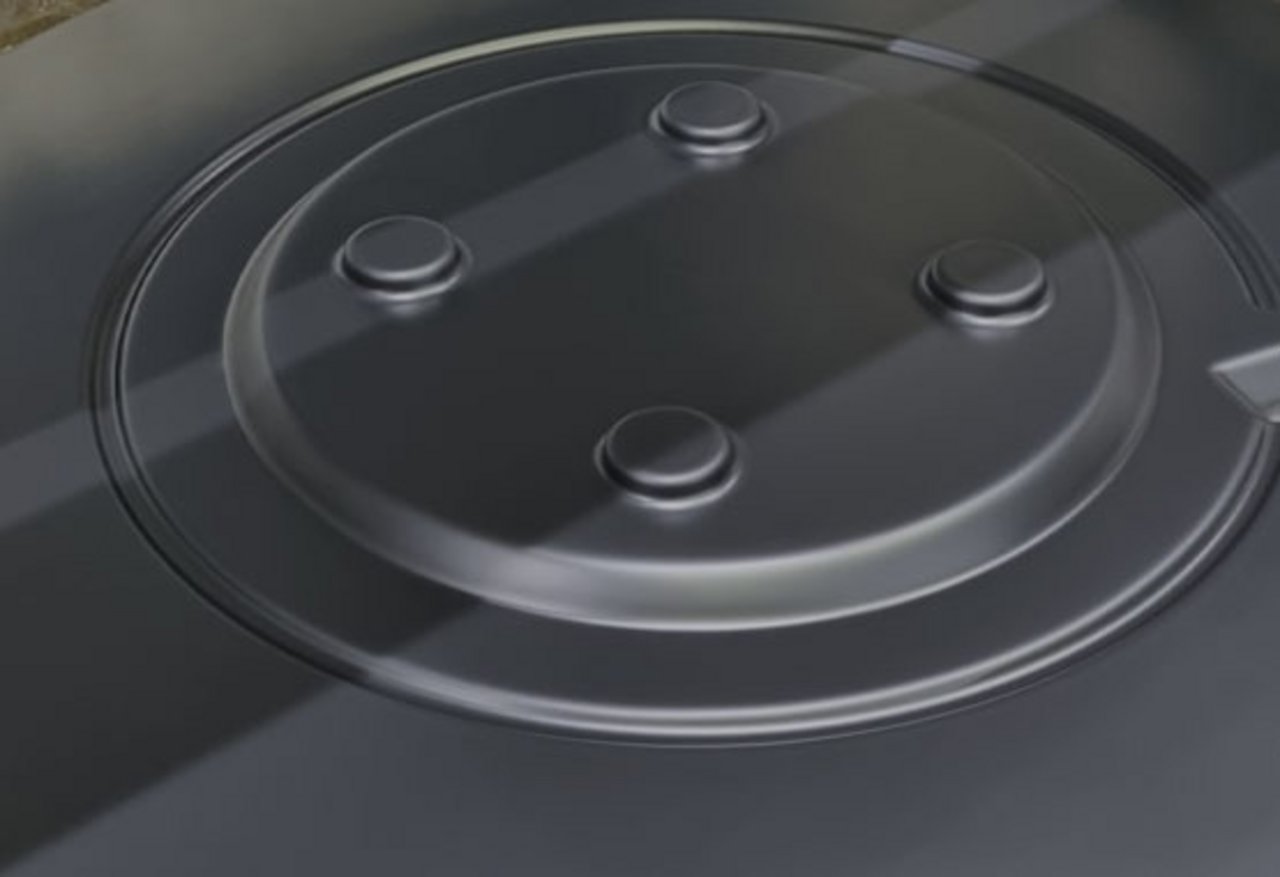

Vacuum shaft for waste water

For example, when designing plastic receptacles for use in a vacuum shaft for waste water, we achieved the necessary stability and durability by using fibre composite technology. This rigid material can withstand the enormous pressure generated by the surrounding soil and is also impervious to moisture.